Latex Dipping Process

Glass molds move into the latex tank. Milky latex material sticks to the surface of the glass molds. And then the coated glass molds moved to the drying room. In order to assure consistent stability and strength, the dipping and drying process is repeated at least twice. Condoms are taken off from the glass molds by water’s under washing. Then you will see the shape of condom that you know well. The process environment is automatically controlled and latex in dipping tank is inspected periodically.

As a professional condom producer, we already improve the dipping line little by little to make it perfect to produce the condom, our line not only can produce the regular thickness condom, we also can produce the soft and thin feeling condoms, and we already successfully produced the line for South African and Brazil clients. welcome inquiry us if you want build own latex condom dipping line.

Email: sales@OEMcondom.com

Best ribbed condoms for her

Best ribbed condoms for her Do ultra thin condoms break easily?

Do ultra thin condoms break easily? Aloe vera water based lubricant gel manufature

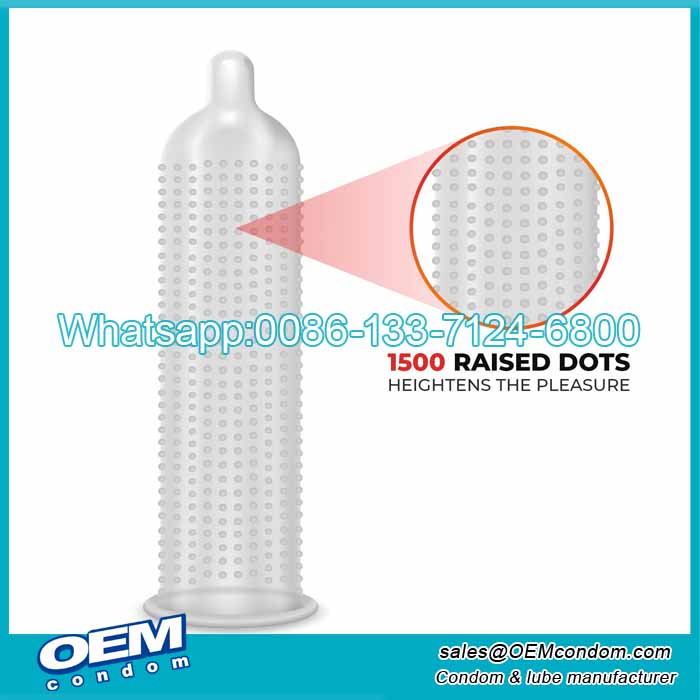

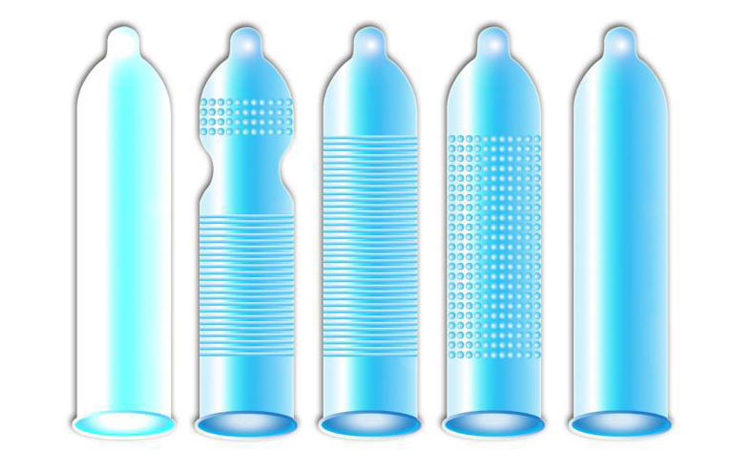

Aloe vera water based lubricant gel manufature Ribbed Dotted Tight Condoms For More Intense and Pleasurable

Ribbed Dotted Tight Condoms For More Intense and Pleasurable different types of personal lubricants and their packages

different types of personal lubricants and their packages